- Welcome to J.K. Pumps Sales & Services

- +91-9711132398, +91-9313090485

- [email protected], [email protected]

Products & Services

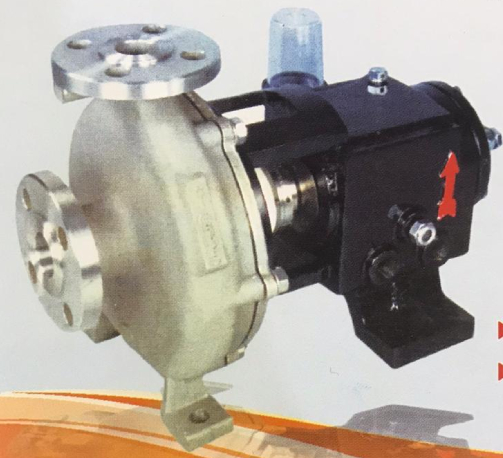

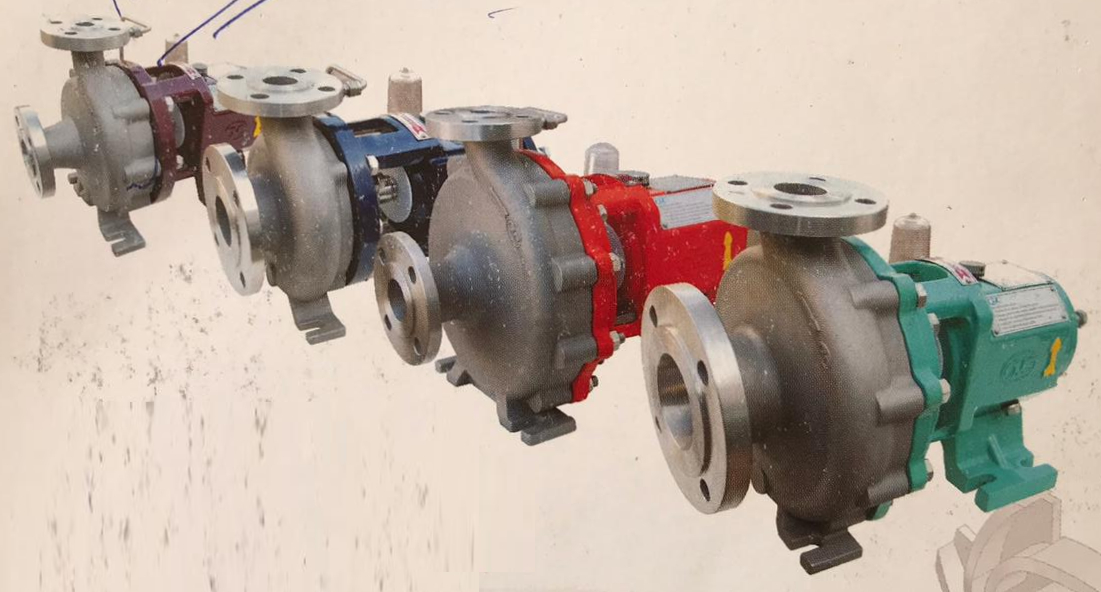

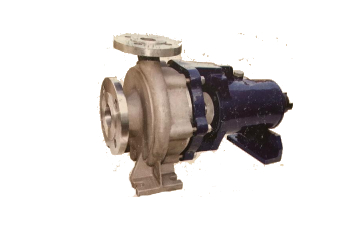

Stainless Steel Pump

Chemical Process Pumps in Investment casting

Specifications

Casing

Top Centre line Discharge, Selfventing Casing. arranged for back pull- out fully confined PTFE gasket. Foot support under Casing for maximum resistance to misalignment and distortion from pipe loads.

Impeller

Fully open, has partial shrouds for maximum vane support without high thrust inherent in full shroud designs.

Impeller is tightened on shaft with nut and threads are sealed by a PTFE 'O' Ring. Impeller nut assures non opening of impeller with wrong rotation of motor. All impellers are statically and dynamically balanced.

Stuffing box cover

Encloses back of casing and contains stuffng box chamber. Cover is fastened to frame. Cover can be supplied with jacket for cooling stuffng box chamber in high temperature services-Jacket can also be used for heating viscous or high freezing point liquids.

Packed box has 4 rings of packing and a lantern ring. Quench gland with taps and an auxiliary ring of packing is standard. Gland is split for easy removal. Tapped openings to lantern ring permit "in and out" sealing, external flushing or lubrication as required.

Stuffng box is completely machined for mechanical seal installation for inside, outside, unbalanced, balanced, single seals.

Bearing frame

Sturdy cast iron construction provides rigid bearing alignment and shaft support. Contains large oil reservoir with water jacket. Oil, level is maintained by constant level oiler with visible oil supply. Oil seals on each end and oil breather fully protects or form contamination while allowing for expansion or contraction of air caused by ambient temperature change.

Shaft

A single piece shaft is designed for 0.05mm maximum deflection at stuffing box face.All critical surfaces ground to less than 0.8micron

Shaft sleeve

Renewable shaft sleeve is positive driven, key way type with one end free to expand with temperature variations. PTFE 'O' -ring prevents

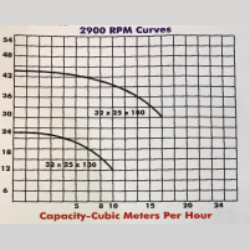

open impeller centrifugal process pump

closed impeller centrifugal process pump

FEATURES:

- BacWpull out esign permits quick inspection, *ring of Rotary assembly without disturbing the pipeline & motor connections-lower maintenance time

- Closed impeller suitable for handling clear Liquid

- Higher efficiencies

- Good for transferring volatile & explosive Fluids

- Maximum interchangeability - minimum spare parts inventory to be maintained

- Serrations on suction & delivery flanges for good sealing (Rest Faces)

- Mechanical seal options available from single, double, tandem, balanced, unbalanced, single spring, multispring, inside, outside

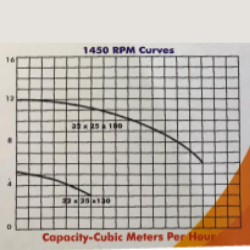

fully open turbine type vertical in-line self priming pumps

FEATURES:

- Fully open impeller for clear fluid transfer

- Low NPSH required

- Best suited for lifting various clear solvents from tank farms to charging vessels or simple drum unloading

- Low speed application (1450 RPM)

- High head low capacity pumps can Lift Fluid from 3-5 Meter

- Standard Carboivs Ceramic faces of mechanical seal, seals the fluid inside the pump

- Mechanical seal is cooled by fluid inside the pump no additional cooling arrangement required

- Floating impeller design

- Suitable only for clear fluids

- Trolley for mobile operation available

- Requires lesser space for installation as motor is mounted over the pump