- Welcome to J.K. Pumps Sales & Services

- +91-9711132398, +91-9313090485

- [email protected], [email protected]

Products & Services

Polyvinylidene Fluoride Pumps

Leading Wholesaler of PVDF Pump, Polyvinylidene Fluoride Pumps and PVDF Pumps from Delhi.

Alfa PVDF Chemical Process Pumps

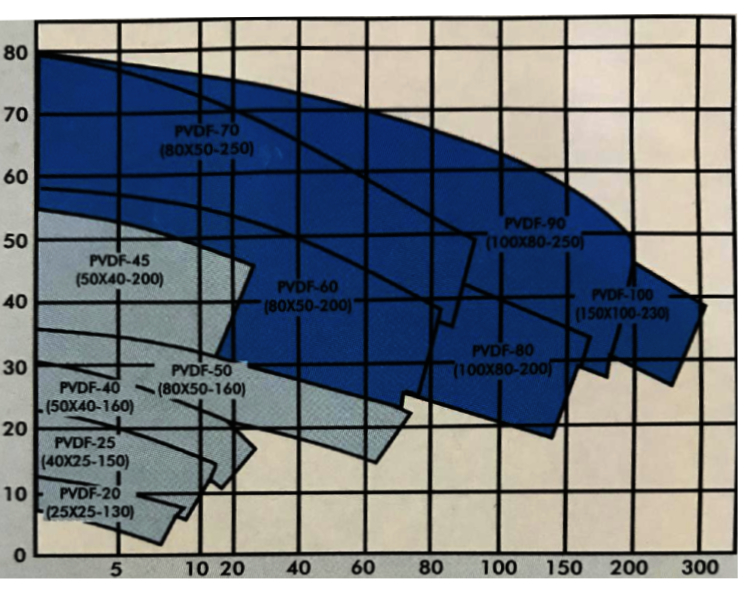

Characteristic Curves at 2900 rmp (50 Hz)

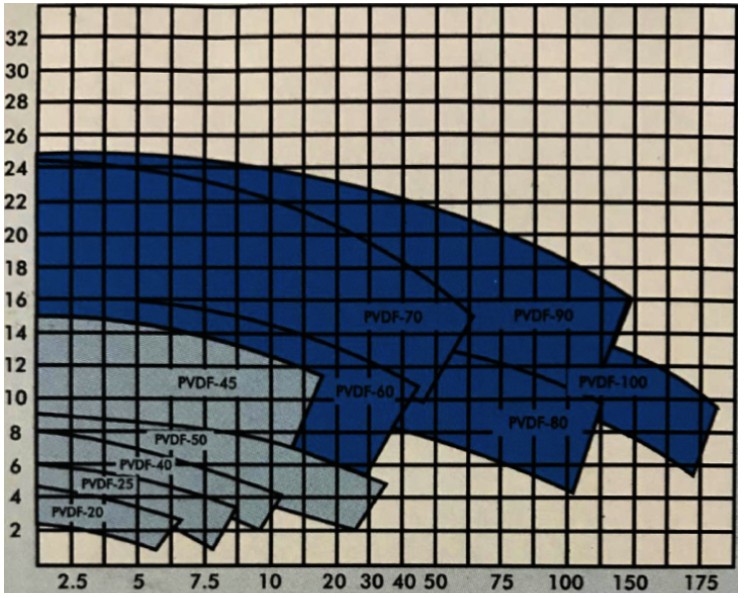

Characteristic Curves at 1450 rmp (50 Hz)

Alfa PVDF Chemical Process Pumps

| Temperature (deg. Celsius) | 110 |

| Speed (RPM) | 1440,2900 |

| Motor Capacity (HP) | 3 to 40 |

Efficient & Dependable for:

- Acids

- Caustic

- Plating solution

- Effulent treatment

- Waste water treatment

- Flow up to 18m3/hr.

- Head up tp 20mtrs

- S S cantilever shaft protected by heavy walled Polypropylene Sleeve

- Heavy duty cast iron motor support with ball bearing seprations pump shaft and motor shaft

- Rugged glassfilled polypropylene Impeller for long life

- Standard available submersible length: 250mm | 500mm | 750mm | 1000mm

Vertical Pumps | VSP Series

Heavy duty vertical submersible pumps in moulded polypropylene

Model Suction Discharge HP (kw) RPM

VSP - 25 1” 1” 1 (0.75) 2900

VSP - 40 1.5” 1.5” 2 (1.5) 2900

Models available, sizes & technical details:

(Head Vs Capacity)

25

20

15

10

5

0 2 4 6 8 10 12 14 16 18 20 22

Capacity M3/Hr

Head Mts

VSP - 25

VSP -40

Polyvinylidene Fluoride Pumps

Polyvinylidene Fluoride (PVDF) offers the specific advantage of easy processing in accordance with all the convection methods used in the plastic industry. PVDF, polymerized, according to its own special process, offers a high degree of crystallinity to that by other processes, resulting among other things, in superior thermomechanical properties.

The pump has special stable-bearing pedestal which assures smooth running even during difficult applications and thus receiving optimum pre-conditions for a long life-time of the mechanical shaft seal.With respect to its shaft deflection, its robust design provides the pre-conditions which meet with international standards,

Vertical Dry pit Sewage pumps:

For a long life-time of the mechanical shaft seal.With respect to its shaft deflection, its robust design provides the pre-conditions which meet with international standards, especially in case of heavy load e.g. starting against open discharge valve, minimum flow rates, maximum impeller diameters and high density.Having sturdy & defect free design with solid PVDF housing, which is completely encapsulated in an outer metal armour. Together they provide chemical & thermal resistance and mechanical strength to the pump. The development of heavy-duty PVDF series is based on long-term experiences with the proven KLCP series. Compared to the KLCP series the very strong shaft design is the substantial construction feature of the PVDF series improvement further important components were designed to supply even more operational safety.

Advantages:

1.Tried and tested chemical process pump design for rough conditions

2.Thick-walled vacuum-proof plastic housing in one piece

3.Plastic housing encapsulated in tough material

4.Pipeline process are absorbed by the metal armour

5.Ideal for high system pressures

6.Flanges with through holes meeting the requirements of the the chemical industries

7.Semi-open PVDF impellers reinforced by large metal inserts

8.Smooth running and durability of the mechanical seal

9.Modular system ensuring cost effective spare parts stocking

10.External corrosion protection of pump and base plate by an epoxy paint

Performance

1.Flow rate upto 300 M/Hr.

2.Pump size chosen as per ISO/DIN enabling economical spare specifications parts stocking

3.Head upto 90 mts liquid column